Dynamic Jet 2.0

DYNAMIC Jet 2-0

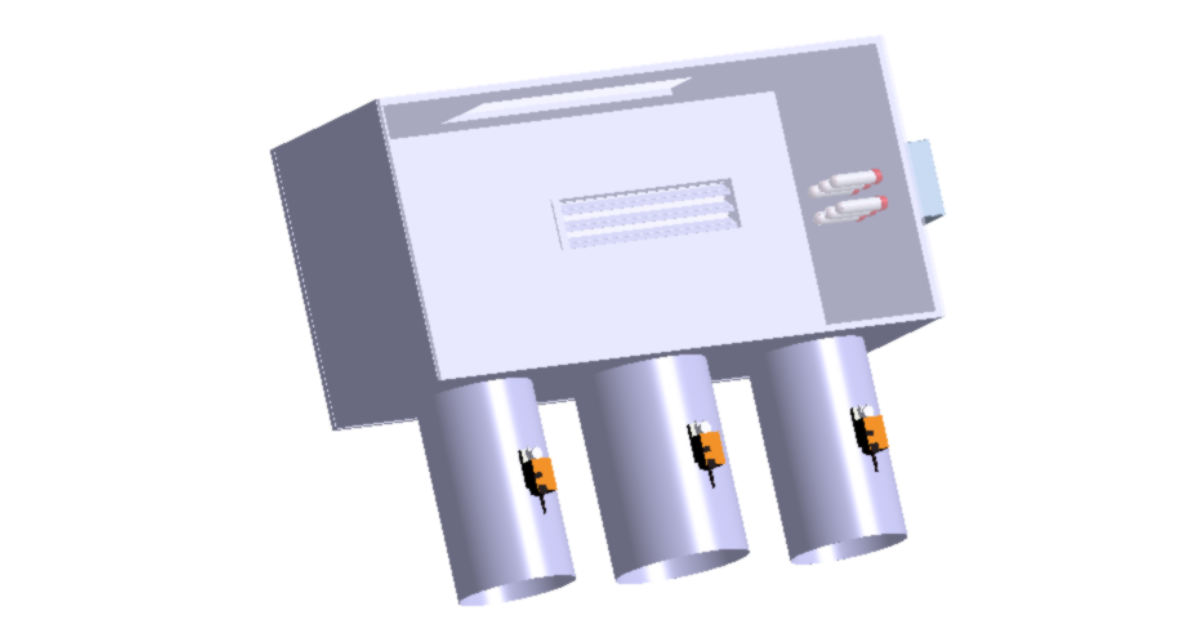

The DYNAMIC jet 2.0 system is an advanced solution for air treatment in environments where a change in the flow rate of the system is necessary. This is particularly useful in places with endogenous loads that vary over time, such as exhibition centers, industries, meeting rooms and restaurants. Using high induction diffusers, the system ensures stable flow and pressure conditions for optimal operation.

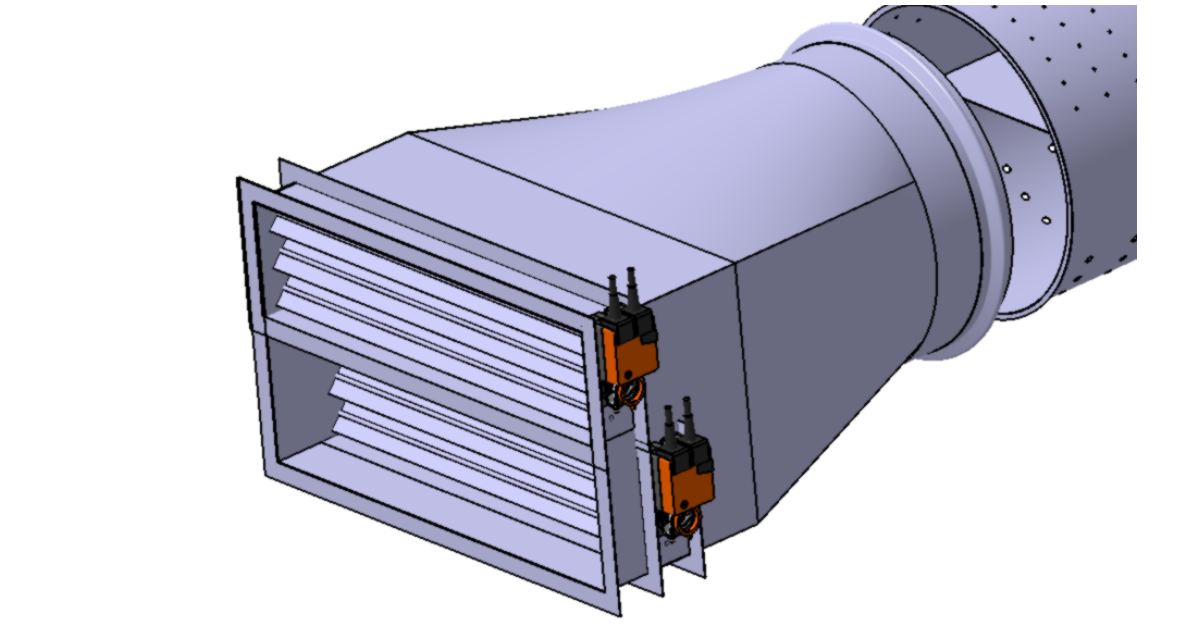

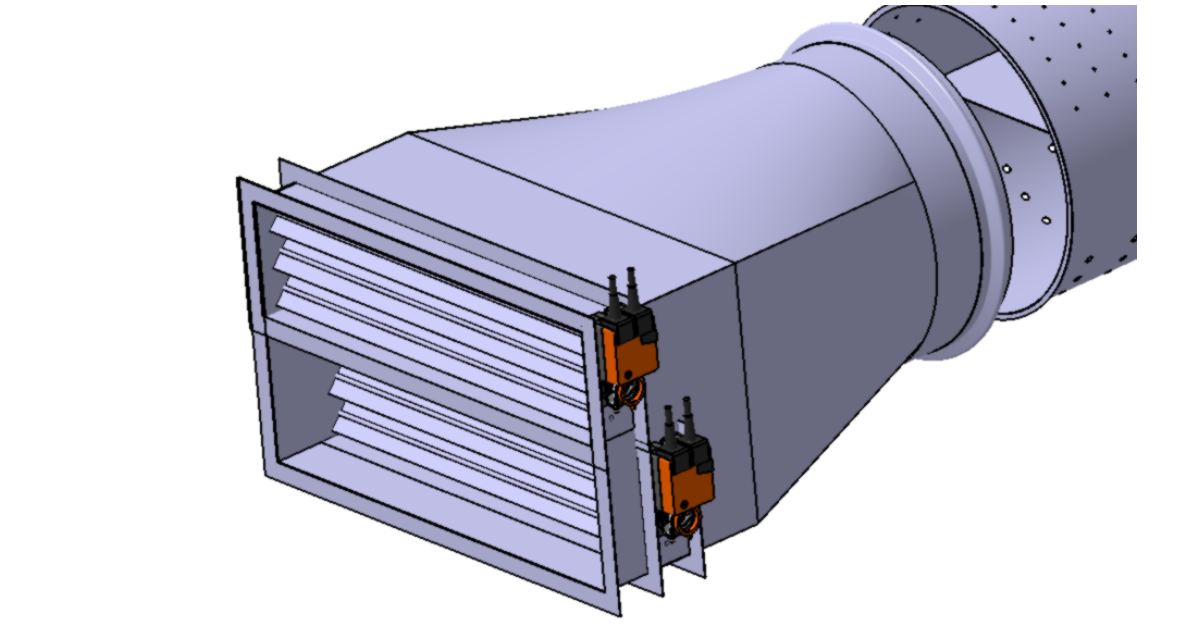

The DYNAMIC jet 2.0, a revolution in the system, guarantees constant pressure and flow in the primary diffuser through a retro-operatable damper system. This control can be managed both via sensors and electronic control unit (PLUS range) and mechanically. This ensures a constant air throw on the primary diffuser, allowing optimal air mixing.

In situations of increased power, the primary diffuser adjusts, while the secondary diffuser opens the dampers to distribute the excess flow. Each diffuser is controlled by motorized dampers managed by an electronic microprocessor.

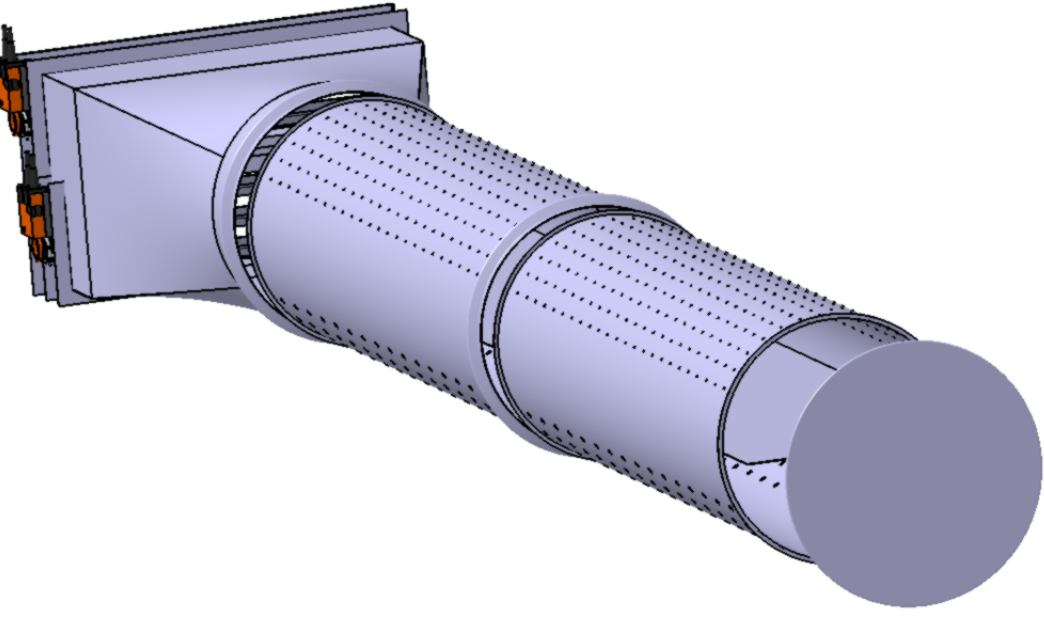

DYNAMIC Jet Mono

The Dynamic Jet Mono Project takes air distribution to new levels of perfection. The circular duct, with its metal plate and motorized dampers, is equipped with a pressure sensor that automatically adjusts the distribution, ensuring a uniform and comfortable air throw.

Possibility of modulating the system flow rate from 30% to 100% for greater comfort. Optimal heat distribution, homogeneity of conditions in the environment and maximum system efficiency. Energy saving, thanks to the elimination of stratification.

Advantages at a glance

Possibility to modulate the flow from 30% to 100% for greater comfort…

Optimal heat distribution, uniform environmental conditions and maximum system performance.

Energy saving, thanks to the elimination of stratification.